Putaway Common Issues

Frequently encountered putaway problems and their solutions

The operator scans the Inbound TSU barcode, but cannot proceed

Section titled “The operator scans the Inbound TSU barcode, but cannot proceed”Solution: Operators are expected to escalate the issue to a supervisor/administrator, who can check the manifest page to see if the manifest exists.

If the manifest does not exist, the administrator should create a manifest. In Voyager WMS, ingest the tote to the AUTOSTOREPUTAWAY location. This can fail if the slotting rules are incorrectly configured, or a product override exists for the wrong pickface.

The Putaway task is not selectable from the select workflow screen, as the button is disabled

Section titled “The Putaway task is not selectable from the select workflow screen, as the button is disabled”Solution: Check that the port the operator is working on has content codes configured on the Port Configuration page.

When the operator chooses a bin type, they are presented with “There are no tasks or bins that match the port’s select requirements. (ERROR CODE: 1015)”

Section titled “When the operator chooses a bin type, they are presented with “There are no tasks or bins that match the port’s select requirements. (ERROR CODE: 1015)””Solution: Check the port is properly configured to receive bins using the Port Configuration page. Check that there are bins in the AutoStore for the configured types, this error can occur when there are no more bins available for the AutoStore to provide to the operator.

When the operator is putting away, the system suggests more than will fit or the operator could fit much more in

Section titled “When the operator is putting away, the system suggests more than will fit or the operator could fit much more in”Solution: The value shown on the putaway screen will be the greater of the products per compartment value, or the remaining stock on the manifest.

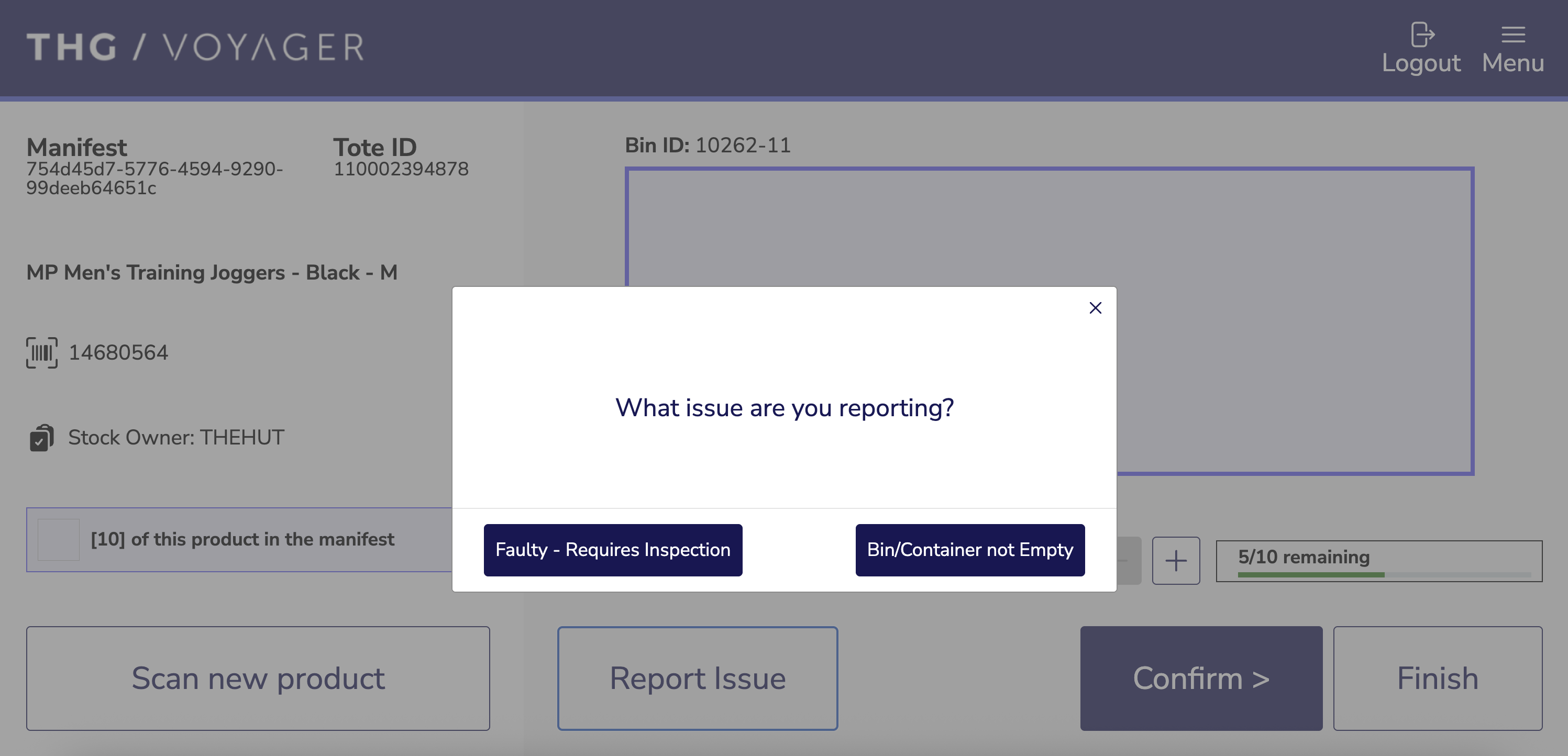

The WCS suggests that the user fill a compartment that already contains stock.

Section titled “The WCS suggests that the user fill a compartment that already contains stock.”Solution: Use the ‘Report Issue’ button on the putaway screen and on the following prompt, press Bin/Container not Empty

The AutoStore will take the bin away, and a ‘Bin Issue’ will be created, to be handled in a separate process.

Manifest Discrepancies

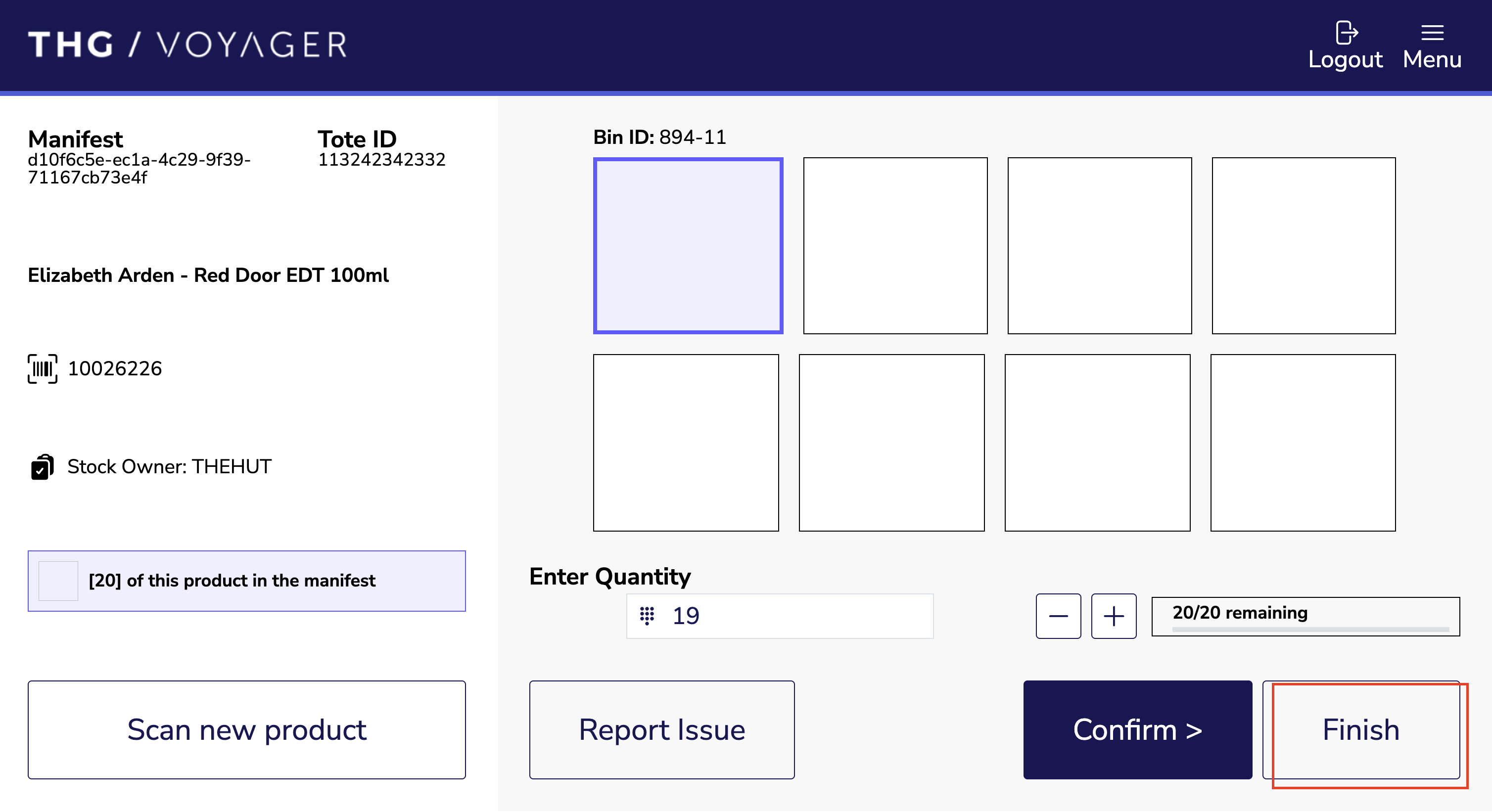

Section titled “Manifest Discrepancies”Problem 1: Extra inventory received in the Inbound TSU

Problem 2: Inbound TSU contains fewer units of inventory than specified

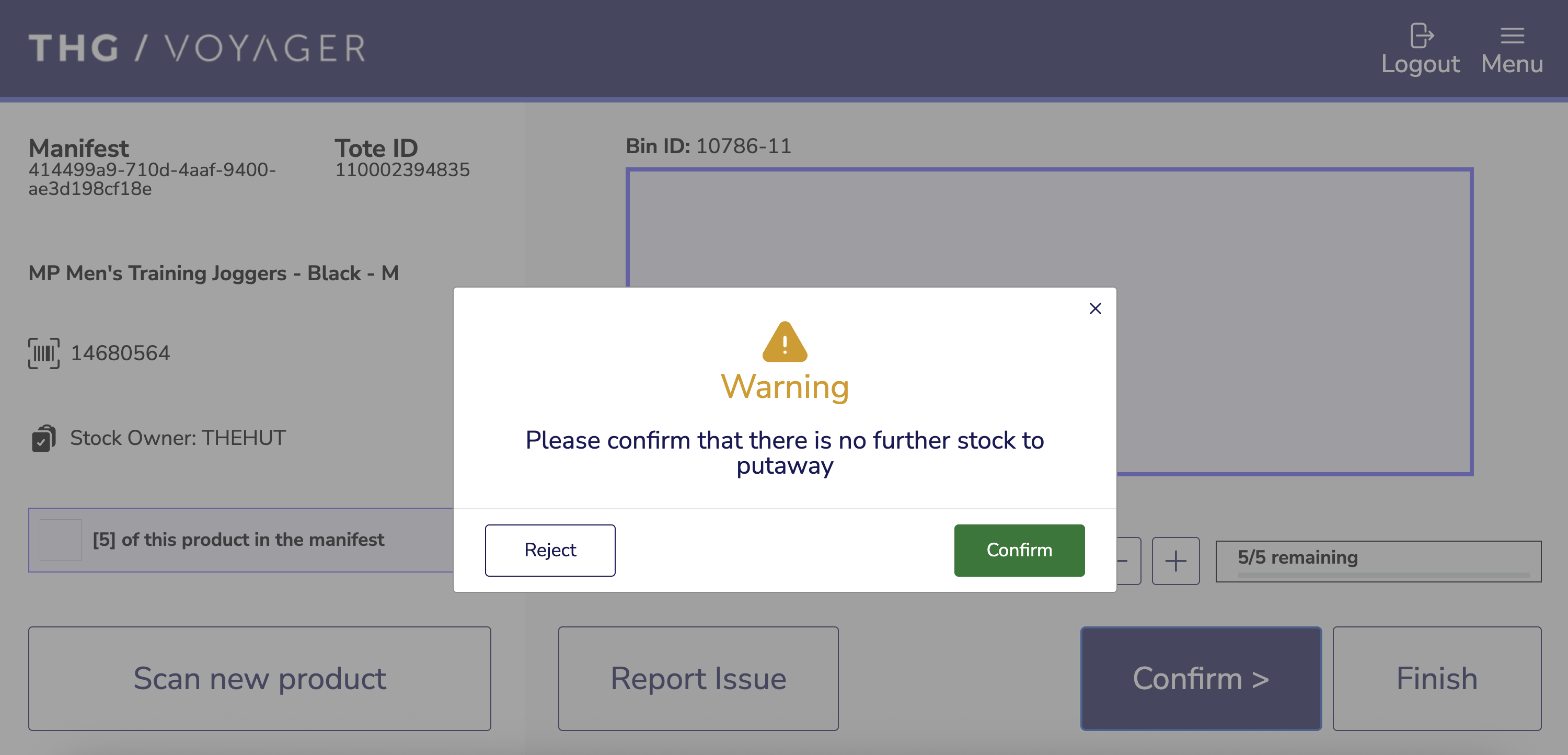

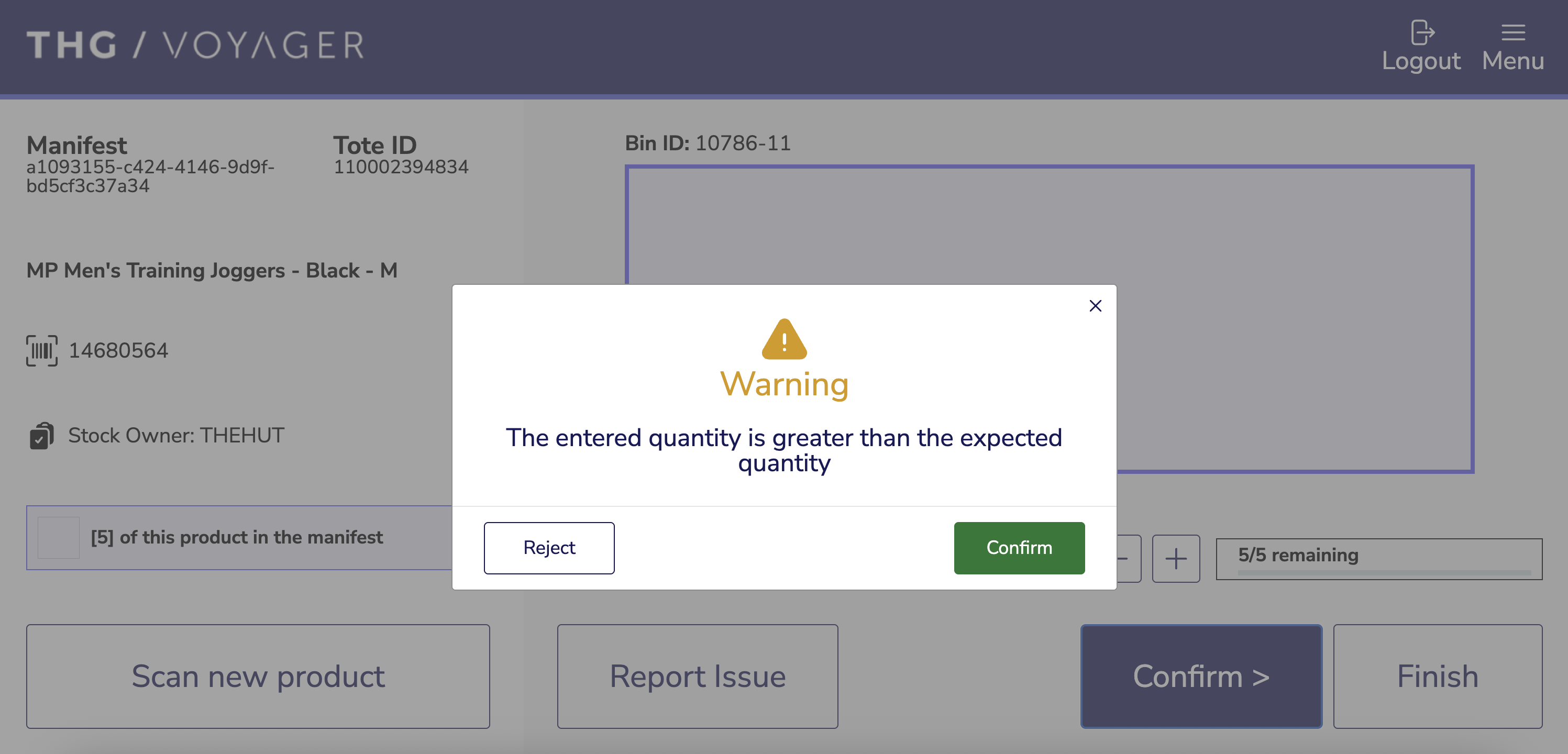

Solution: The operator should continue as normal until the final putaway and enter the values that they have, not what the system expects. If the user has less stock than expected they should press finish:

The system will prompt either to confirm there is no further stock:

Or, to confirm there is more stock than was expected:

Damaged Product in the Inbound TSU from prior processing or handling

Section titled “Damaged Product in the Inbound TSU from prior processing or handling”Solution: If a product arrives at a port damaged, the operator is expected to follow site protocols for damaged products and treat the manifest as normal, handling discrepancies as above.

The WCS will not register the stock. In Voyager WMS, after the putaway is completed the inbound TSU will be marked as empty, clearing any damaged stock.